Need a technical consultant to answer your questions?

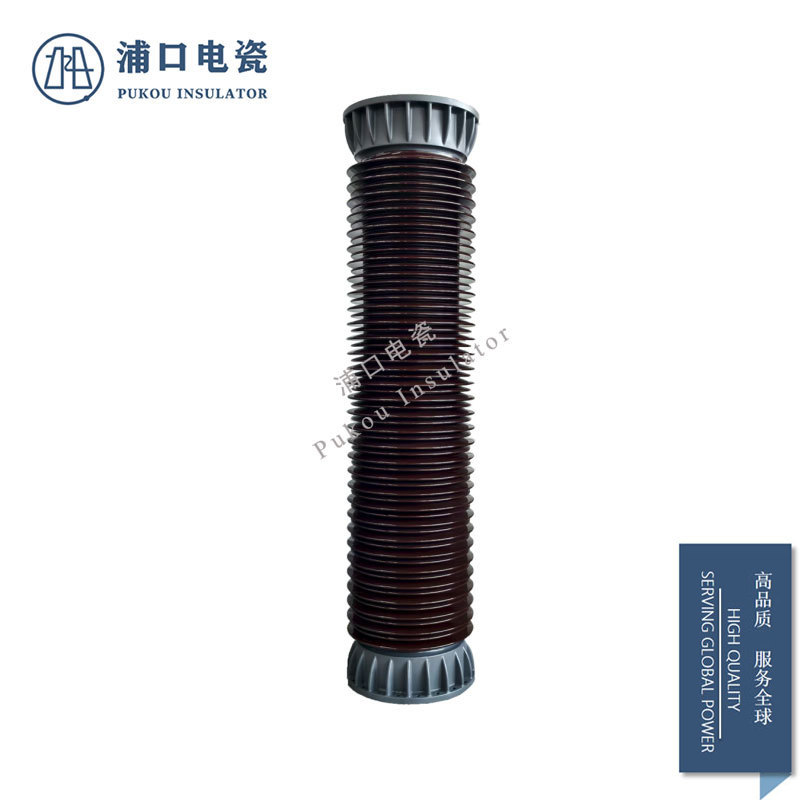

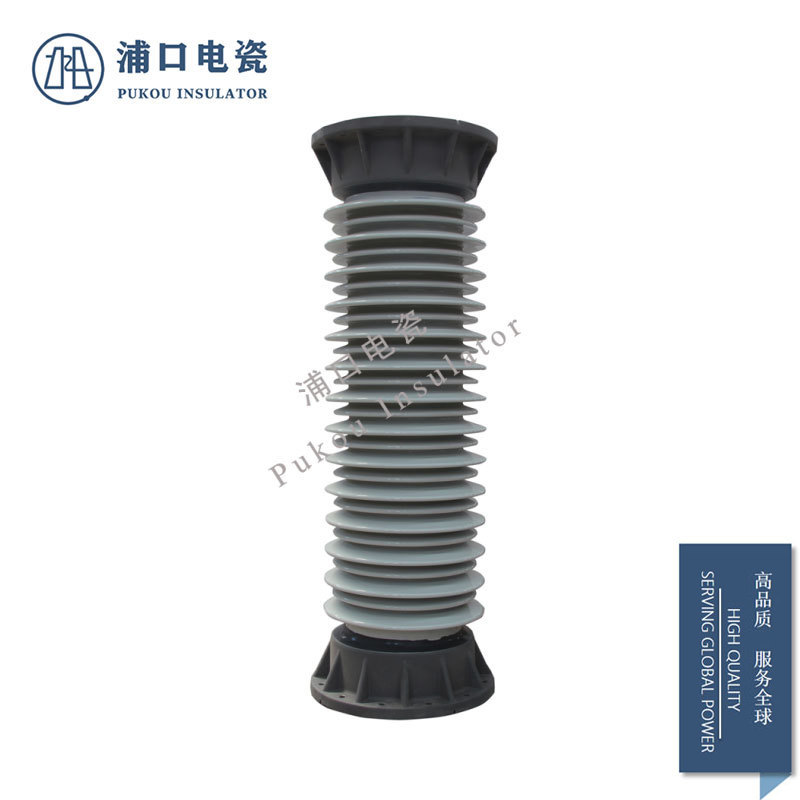

220kV Gas-Insulated Current Transformer Porcelain Bushing

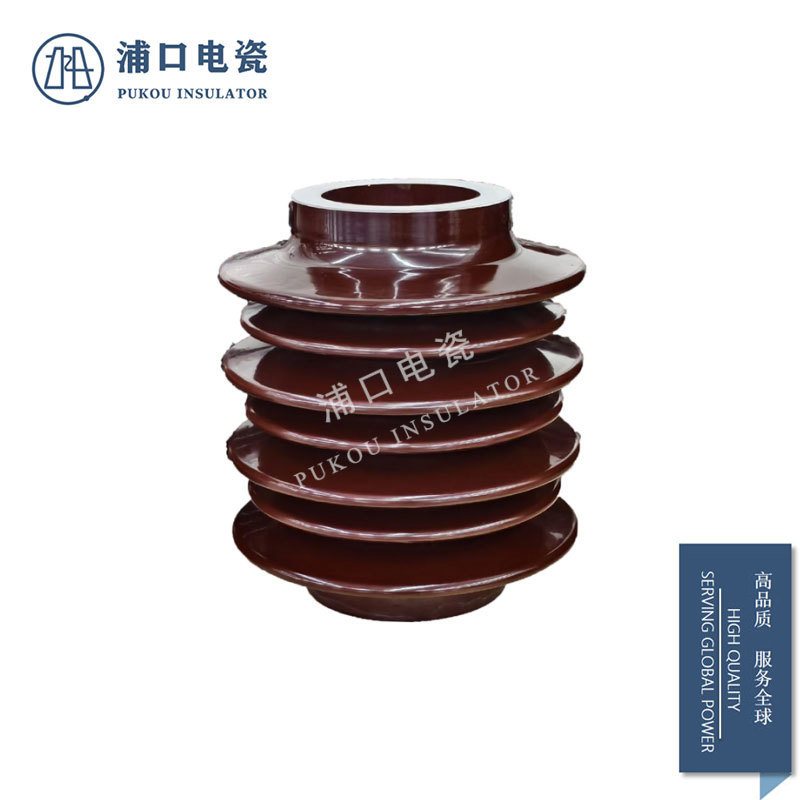

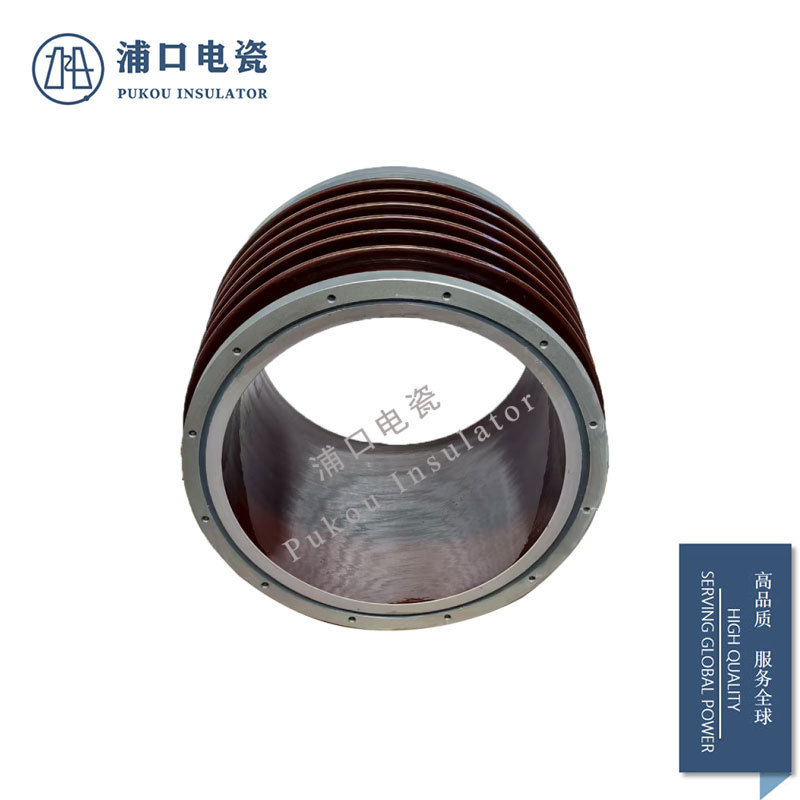

Hollow Insulator

PUKOU INSULATOR

- Product Description

-

- Commodity name: 220kV Gas-Insulated Current Transformer Porcelain Bushing

In modern power systems, porcelain insulators serve as critical components, playing a vital role in supporting energized conductors while ensuring proper insulation—and simultaneously withstanding diverse mechanical loads. From 10kV distribution networks to 1000kV ultra-high-voltage transmission lines, our porcelain insulators consistently demonstrate outstanding performance, safeguarding the safe and stable operation of power systems.

10kV - 1000kV Electrical Porcelain Insulators: A Reliable Guarantee for Power Transmission

In modern power systems, porcelain insulators serve as critical components, playing a vital role in supporting energized conductors while ensuring proper insulation—and simultaneously withstanding various mechanical loads. From 10kV distribution networks to ultra-high-voltage transmission lines reaching 1000kV, our porcelain insulators consistently demonstrate outstanding performance, safeguarding the safe and stable operation of power systems.

I. Product Specifications and Technical Parameters

1. Dimension Range: Our porcelain sleeve products come in a wide range of specifications—organic-bonded sleeves can reach up to 11 meters in length, while inorganic-bonded sleeves are available down to 6mm. Additionally, our fully molded sleeves can achieve an overall length of up to 2.7 meters and a maximum diameter of 1 meter, perfectly meeting the installation needs of various electrical equipment.

2. Voltage Level Coverage: The products cover the full voltage range from 10kV to 1000kV, providing reliable insulation support whether it's for daily power supply in urban distribution networks or for ultra-high-voltage transmission across regions.

3. Mechanical Strength: Made from high-strength porcelain material and processed using a special technique, these products exhibit exceptional resistance to bending and compression. With mechanical strength reaching up to the ton level, they can easily withstand various mechanical loads—including the weight of conductors, wind forces, and seismic pressures—ensuring stable operation even under extreme weather conditions.

4. Insulation Performance: The surface glaze layer is smooth and dense, effectively preventing current leakage. In high-voltage environments ranging from 110 kV to 1000 kV, it maintains stable insulation performance, providing a reliable safeguard for power transmission.

5. Aging Resistance and Corrosion Resistance: Featuring excellent aging resistance and corrosion protection, it can withstand attacks from acids, alkalis, salt spray, and more, ensuring a service life of over 30 years. This significantly reduces the frequency of equipment replacement and maintenance, thereby lowering operational costs.

II. Production Processes and Quality Control

1. Precise Ingredient Blending: Carefully selected high-purity alumina, potassium-sodium feldspar, and other premium mineral raw materials are precisely blended according to exact proportions, ensuring the porcelain body exhibits outstanding mechanical and insulating properties.

2. Molding Process: Using the wet molding process, precise moisture control ensures accurate and consistent product dimensions.

3. High-Temperature Sintering: After high-temperature sintering in a fully automatic drawer kiln, the porcelain body becomes densely compacted. At an elevated temperature of 1250°C, the resulting porcelain boasts a hardness comparable to that of rock, significantly enhancing the product's strength and stability.

4. Surface Treatment: Depending on the specific application environment, special treatments are applied to the surface of insulators—such as spraying with RTV anti-pollution flashover coatings—to enhance the product's resistance to ice buildup and contamination, enabling it to perform reliably in a wide range of challenging climatic conditions.

5. Rigorous Quality Inspection: Each insulator undergoes rigorous quality checks, including mechanical performance tests, electrical performance tests, and non-destructive testing, among other procedures. Only products that pass all these inspections are allowed to enter the market, ensuring customers receive reliable quality assurance.

III. Application Areas

Substation: As the "power backbone" of a substation, insulators support energized equipment while not only isolating high voltage but also bearing the weight of the devices. Their reliable performance provides a solid foundation for the dependable operation of the substation.

IV. Product Advantages

Enduring Extreme Environments: For special regions such as high-altitude and heavily polluted areas, we have developed large creepage distance, ice-shedding insulators that can withstand complex and ever-changing climatic conditions, ensuring the reliable operation of power systems in any environment.

Choosing our 10kV - 1000kV porcelain insulators means selecting outstanding performance, reliable quality, and comprehensive technical support. We are committed to delivering the highest-quality products and solutions to the global power industry, helping drive the thriving development of the electric power sector.

Next page

Next page

Product Message

Contact our team promptly—we’d be happy to assist you!

*Note: Please ensure all information is accurate and keep your contact details updated, as we’ll reach out to you as soon as possible.