Need a technical consultant to answer your questions?

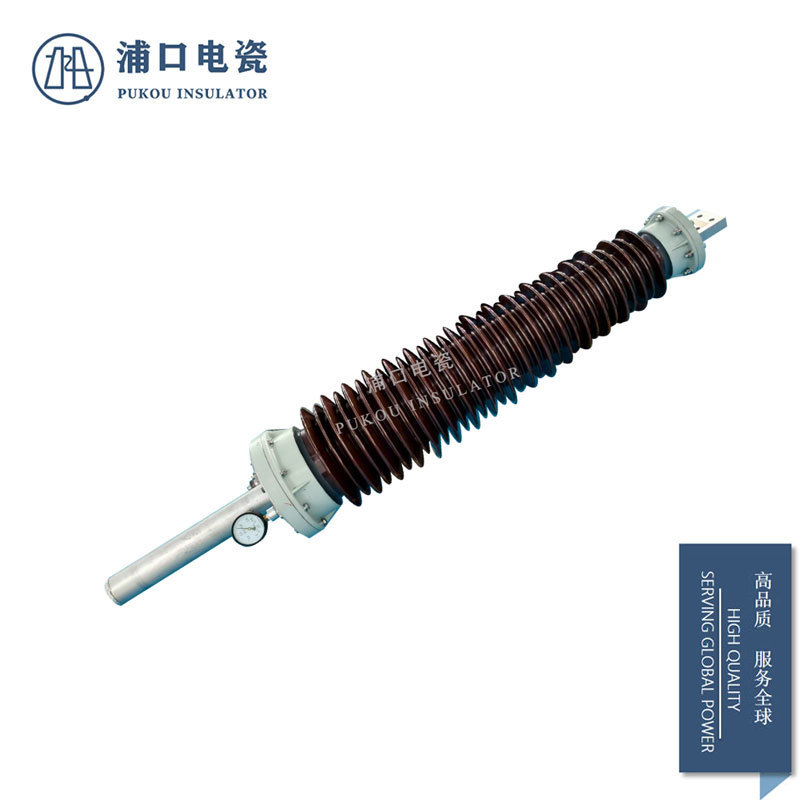

110kV GIS bushing

GIS Bushing

PUKOU INSULATOR

- Product Description

-

- Commodity name: 110kV GIS bushing

With the development of SF6 fully enclosed gas-insulated switchgear (GIS) and the widespread use of GIS bushings, these components boast features such as being lightweight, compact, simple, cost-effective, and easy to manufacture. Notably, their internal insulation is highly reliable, ensuring no interference from partial discharge.

The Advanced Nature of GIS Casing Assembly Technology

1. Overview

As SF 6 The development of fully enclosed gas-insulated switchgear (GIS) has led to the widespread use of GIS bushings, which boast features such as being lightweight, compact, simple, cost-effective, and easy to manufacture. Notably, their internal insulation is highly reliable, ensuring no interference from partial discharge.

Originally, domestic GIS bushings were designed and produced by major switch manufacturers themselves, while hollow porcelain insulators were sourced from external manufacturers. Currently, however, major switch makers are increasingly opting to purchase complete outgoing bushing assemblies directly from suppliers.

Hunan Province Liling City Pukou Electrical Porcelain Co., Ltd. (hereinafter referred to as: Pukou Company) utilizes its own domestically produced porcelain bushings, combined with the advanced manufacturing technologies currently employed by leading switchgear companies. As a result, Pukou Company has developed and is now supplying GIS outlet bushings tailored for use by major switchgear manufacturers. This collaboration allows these companies to focus entirely on mastering overall product assembly and advancing their offerings to even higher voltage levels.

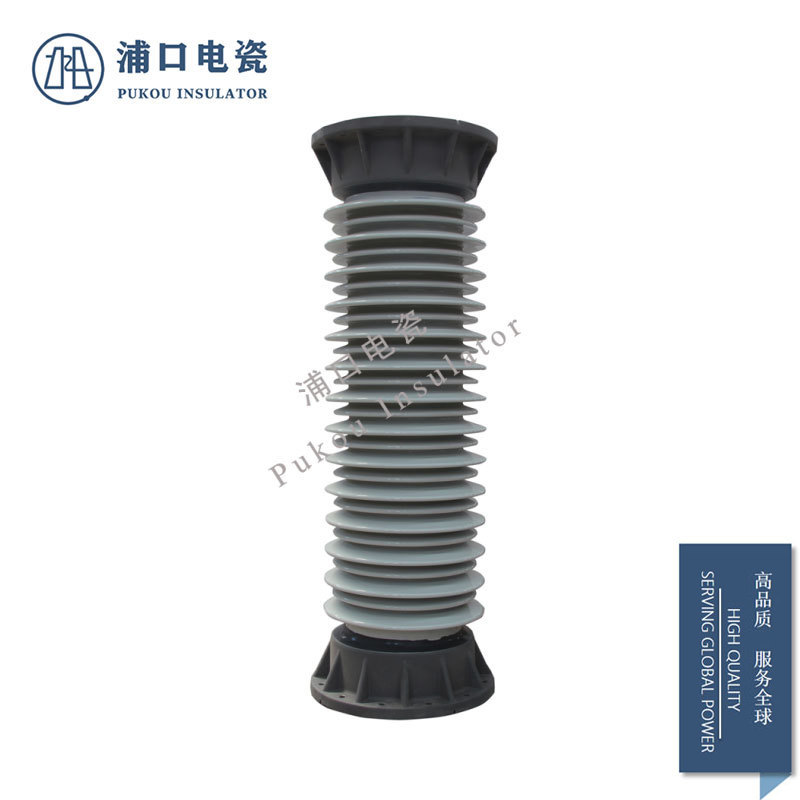

Our company produces a series of GIS equipment rated for 126kV, 252kV, 363kV, and 550kV SF₆. 6 /Air porcelain bushing products, suitable for Pollution Level III and Level IV areas.

2. Product Performance and Structure

2.1 Product Performance Parameters

Our company can tailor product interface designs to meet diverse customer requirements. As of June 2025, we have already assembled a variety of product interface configurations in different formats, all according to user specifications.

2.2 Product Structure

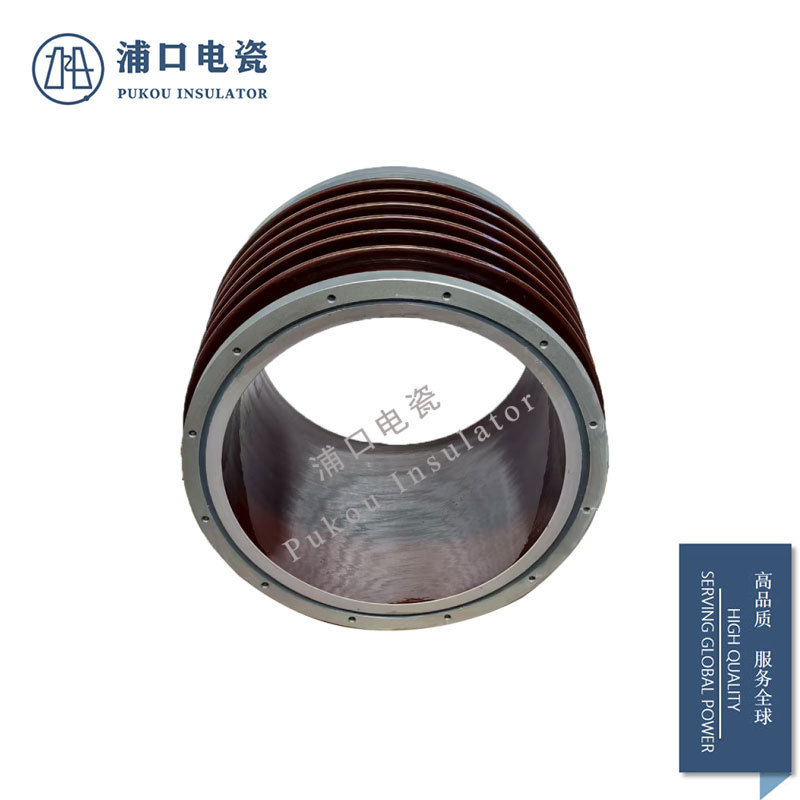

The SF6/air porcelain bushing for GIS serves as the high-voltage inlet and outlet terminal of the GIS, primarily composed of a porcelain sleeve, housing, basin insulator, and grading ring, among other components. It features a single-phase, single-tank design. The high-voltage end is mounted on the connection plate of the central conductor within the outlet porcelain bushing, linking via the central conductor to the contacts of the basin insulator, thereby establishing the internal connection between the system and the GIS enclosure itself. Both the central conductor and the contact connection points are installed inside the tank filled with SF6 gas. 6 Inside the fully enclosed metal container for gases. Due to SF 6 Gases possess excellent electrical insulation properties, effectively enhancing the electrical insulation performance of the bushing and enabling a reduction in the distance between phases and ground.

This product series features porcelain components that can be custom-designed according to customers' installation requirements. Additionally, the installation height of the products can also be tailored to meet specific customer needs, ensuring compatibility with various GIS outgoing configurations. The products boast exceptional insulation capabilities, a compact design, well-organized internal structures, and reliable connections. Moreover, their performance metrics fully comply with relevant standards such as GB/T 4109 and GB 11022, positioning them at the forefront of today's international advanced technology levels.

3 Product Features

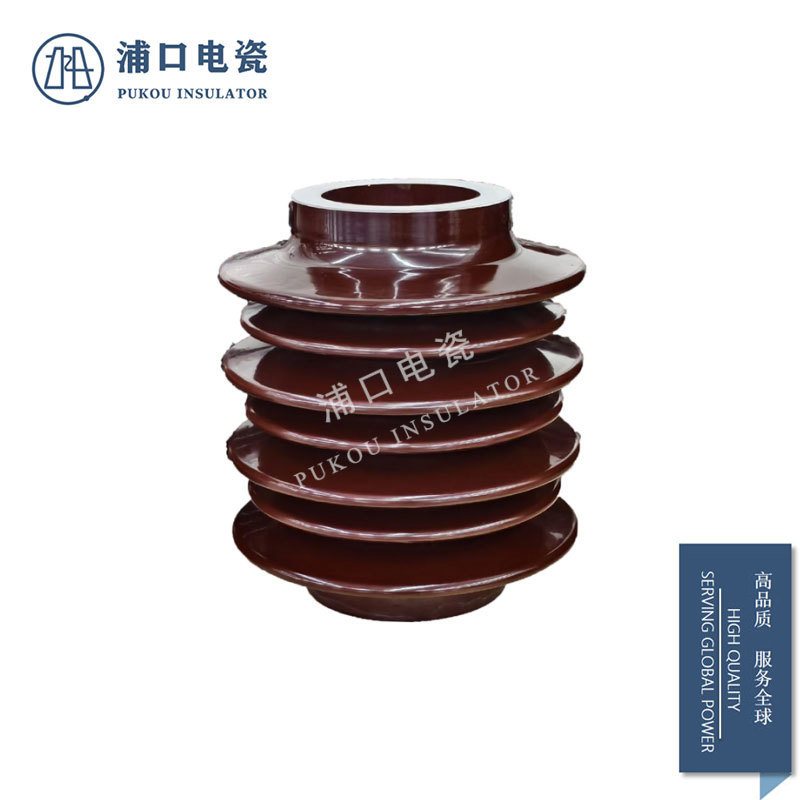

3.1 High-quality porcelain components

The porcelain components are made from high-strength electrical porcelain and produced using a mature process that has been refined over many years. They are manufactured with advanced equipment and undergo rigorous inspection and testing, ensuring the inherent quality of the porcelain parts.

3.2 Precision Product Assembly

Product assembly is a critical technology for GIS SF6/air porcelain bushing products. The precision of the assembly directly affects the final product quality. Each assembly process is supported by dedicated tooling and equipment to ensure accuracy, and every step in the assembly procedure is meticulously guided by comprehensive process documentation.

After years of dedicated practice through the assembly of nearly 2,000 projects, Pukou Company has developed professional expertise in the complete assembly of GIS bushings, mastering the seamless integration of porcelain components with other elements. As a result, their products now achieve optimal performance, craftsmanship, and aesthetic appeal.

3.3 Precise Product Control

From the procurement of raw components at the product's source to in-house inspection, and from cleaning product parts to assembly—every single process step has been meticulously documented in detailed assembly procedure cards, ensuring that product assembly is conducted in an orderly, accurate, and complete manner. The following key measures have been implemented:

a. Specialized inspection fixtures, such as dedicated templates, have been designed to ensure the accuracy of product inspections.

b. Designed specialized assembly fixtures to ensure the geometric and positional tolerance requirements of the assembly interfaces.

c. Optimized the electrical testing fixtures to ensure accurate and error-free product inspection.

d. Optimized the product assembly process cards and implemented assessment and inspection for each work step, ensuring precise product assembly.

e. Dedicated personnel are responsible for incoming inspection of products and product testing, ensuring consistent product quality.

3.4 Excellent Product Performance

Among them, the 252kV porcelain insulators selected are our company's standard product 59610, which passed the 1-minute power-frequency withstand voltage test at 490kV—exceeding the national standard of 460 kV for 1-minute withstand voltage.

4. Technical Assurance Measures

4.1 Mature Wet-Process Porcelain Manufacturing Technology and GIS Outgoing Porcelain Bushing Assembly Techniques

After continuous improvement and refinement, Pukou Company has masterfully mastered the wet-process porcelain insulator production technology. They have compiled more than 80 standardized operation manuals, including those for manufacturing large hollow porcelain insulators with inorganic bonding, covering every step from raw materials to product inspection and packaging. This has resulted in a technology and process system equipped with independent intellectual property rights, enabling precise guidance throughout the entire production process.

GIS using SF 6 The assembly process for air porcelain bushings relies on the mature assembly technologies developed by major switchgear companies' GIS systems, refined over nearly 1,000 projects involving more than 9,000 products. Tailored to the specific needs of Pukou Company, this process incorporates and integrates advanced assembly expertise from leading switchgear manufacturers, resulting in the creation of multiple standardized operation guides—including procedures for cleaning, assembly, and sealant application—to meticulously guide the assembly of GIS outlet bushings.

4.2 Testing and Inspection of Products

Pukou Company provides GIS-grade SF6 gas to major switchgear manufacturers. 6 /Air porcelain bushings must undergo the following tests before leaving the factory, as required by the technical agreement: visual inspection, dimensional and geometric tolerance checks, gas-tightness testing, lightning impulse tests, power-frequency dry withstand voltage tests, partial discharge measurements, and loop resistance measurements. In addition, porcelain bushings and SF 6 Routine test and inspection report for empty porcelain bushings.

5. Market Fulfillment Capability

Pukou Company's production capacity for SF6 gas used in 126kV to 550kV GIS. 6 /Air porcelain bushings: 6,300 units per year, including 1,260 units at 126 kV, 3,000 units at 2400 kV, 300 units at 363 kV, and 600 units at 550 kV.

Previous page

Next page

Next page

Product Message

Contact our team promptly—we’d be happy to assist you!

*Note: Please ensure all information is accurate and keep your contact details updated, as we’ll reach out to you as soon as possible.