Need a technical consultant to answer your questions?

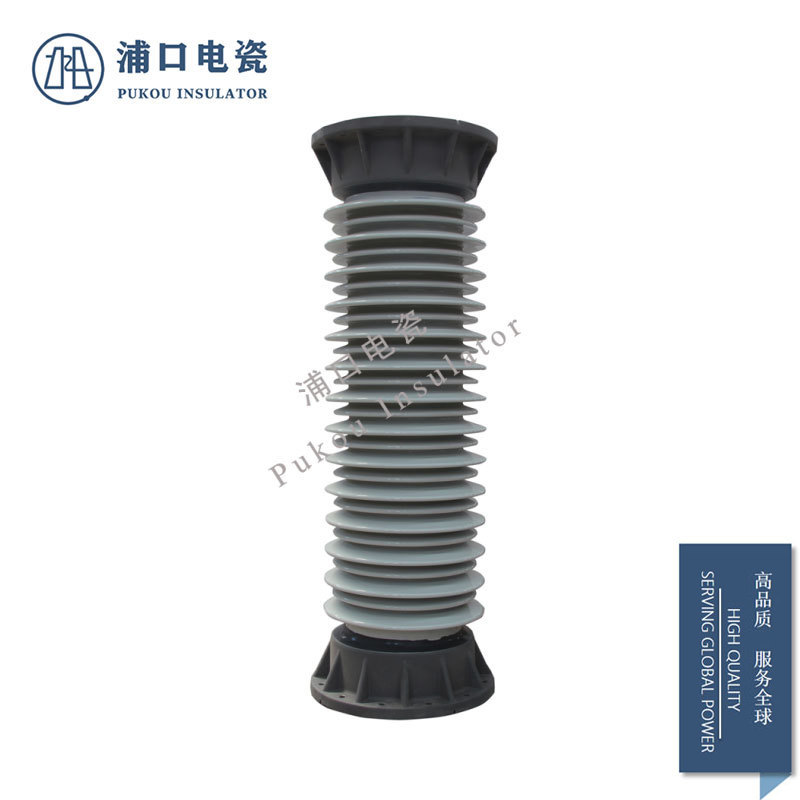

Pipe bus

Pipe bus

PUKOU INSULATOR

- Product Description

-

- Commodity name: Pipe bus

In modern power systems, pipeline busbars—emerging as an advanced power transmission device—are steadily gaining prominence. With their outstanding performance and innovative design, they have become a key element in enhancing both the efficiency and reliability of electricity transmission. From power plants to substations, and further to various industrial and residential power consumption sites, pipeline busbars play an indispensable role.

Pipeline Busbar: A Revolutionary Choice for Power Transmission

In modern power systems, the pipe busbar—a cutting-edge power transmission device—is steadily gaining prominence. With its outstanding performance and innovative design, it has become a key element in enhancing both the efficiency and reliability of electricity transmission. From power plants to substations, and all the way to various industrial and residential power consumption sites, the pipe busbar plays an indispensable role.

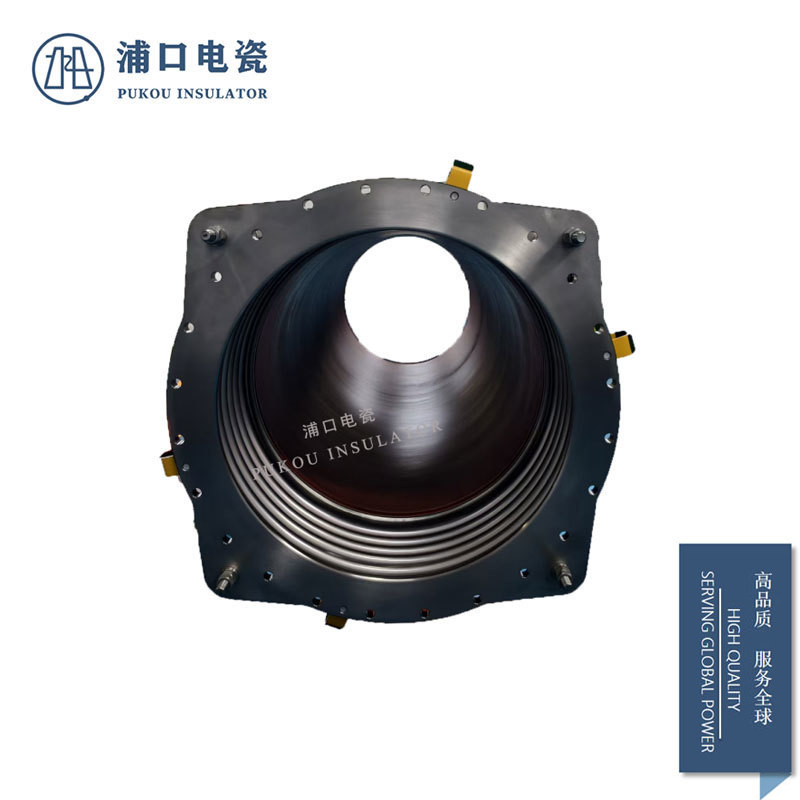

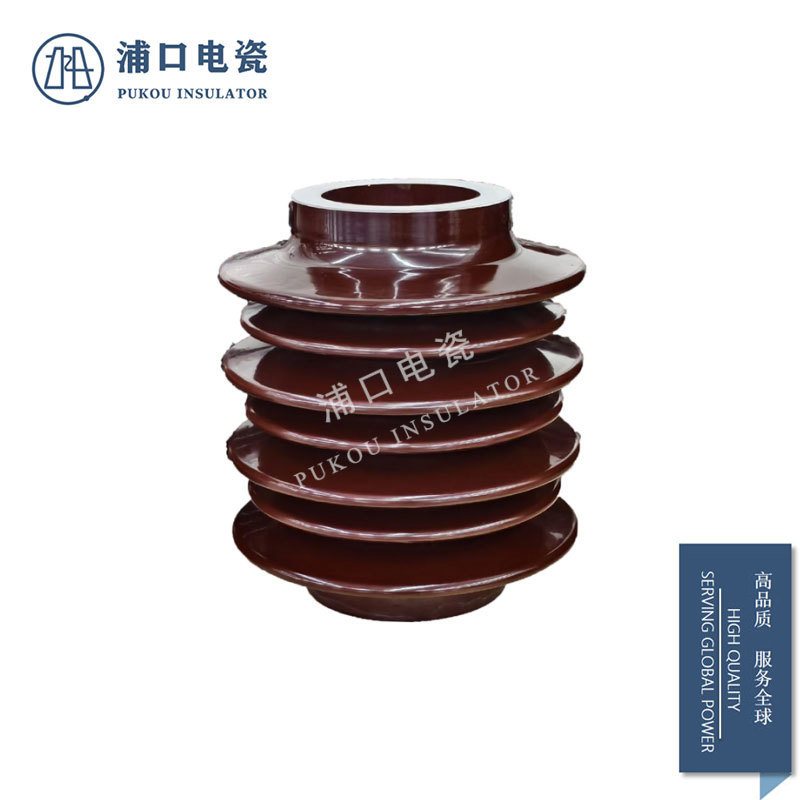

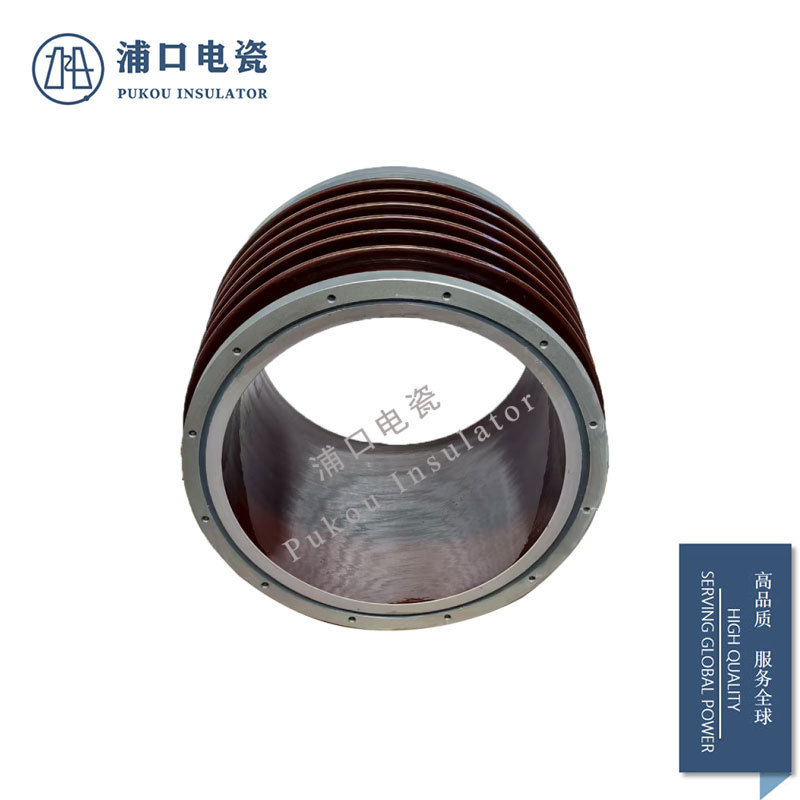

I. Exquisite Structural Design

The busbar system primarily consists of conductors, an insulation layer, and an outer casing. The conductor section is typically made from high-purity copper or aluminum, shaped into hollow tubes through a specialized manufacturing process. This tubular design significantly optimizes current distribution, effectively minimizing the skin effect, allowing the current to flow uniformly across the conductor's surface. As a result, the system dramatically enhances its current-carrying capacity while substantially reducing energy losses.

The insulation layer is made from high-quality insulating materials such as polytetrafluoroethylene and cross-linked polyethylene. These materials boast exceptional electrical insulation properties, enabling them to reliably prevent current leakage even under high-voltage conditions, thus ensuring the safe operation of equipment. At the same time, the insulation layer also exhibits excellent weather resistance and corrosion resistance, making it suitable for a wide range of harsh environmental conditions.

The outer casing typically uses lightweight, corrosion-resistant materials such as aluminum alloy. Not only does it provide robust physical protection for the internal conductors and insulation layers, shielding them from damage caused by external impacts, but it also effectively blocks external electromagnetic interference, ensuring stable power transmission. Moreover, the use of an aluminum alloy casing significantly reduces the overall weight, making installation and maintenance much more convenient.

II. Outstanding Performance Advantages

(1) Strong Current-Carrying Capacity

The hollow tubular conductor design of the busbar features a large surface area, delivering exceptional heat dissipation performance. This allows it to carry far more current than conventional busbars, fully meeting the high-current transmission demands of large-scale power equipment and areas with heavy electrical loads—significantly enhancing both the efficiency and stability of power delivery.

(II) Excellent Insulating Properties

The use of a multi-layered insulation structure combined with high-quality insulating materials endows the busbar with exceptional insulation performance. In high-voltage environments, it effectively prevents current breakdown and flashover phenomena. Even under harsh conditions such as humidity, dust, and pollution, its insulation properties remain consistently reliable. For instance, in substations located in coastal areas prone to salt spray, the busbar has demonstrated outstanding insulation performance, maintaining stable operation over extended periods without a single insulation failure, thereby ensuring the safe and reliable functioning of the power system.

(III) Excellent Mechanical Strength and Stability

The structural design of the busbar system ensures high mechanical strength, enabling it to withstand significant mechanical stresses, short-circuit electromagnetic forces, as well as vibrations and impacts from external environmental factors. In power facilities located in regions prone to frequent earthquakes, the busbar system can maintain its structural integrity even during natural disasters like seismic events, allowing it to continue operating normally. This demonstrates remarkable stability and disaster resilience, significantly reducing power outages caused by equipment damage—and ultimately providing a reliable electricity supply that supports both societal and industrial activities.

(IV) Lower Maintenance Costs

Thanks to its excellent sealing performance and resistance to external environmental factors, the failure rate of pipeline busbars has been significantly reduced, leading to a substantial decrease in daily maintenance tasks. Moreover, the materials used boast outstanding aging resistance, ensuring a long service life—typically lasting over 30 years. This not only minimizes the frequency and cost of equipment replacement but also helps power operators save considerable human, material, and financial resources.

Product Message

Contact our team promptly—we’d be happy to assist you!

*Note: Please ensure all information is accurate and keep your contact details updated, as we’ll reach out to you as soon as possible.